Electric motors power our world. From the fan cooling your room to the electric car zooming down the highway, these devices transform electricity into motion with remarkable efficiency. But how do they work? In this post, we dive into the fascinating mechanics of electric motors, breaking down their components, principles, and real-world applications. By the end, you’ll grasp the magic behind these machines and appreciate their role in modern life.

What Is an Electric Motor?

An electric motor converts electrical energy into mechanical energy. It’s a device that uses electric current and magnetic fields to produce motion, driving everything from household appliances to industrial machinery. Unlike engines that burn fuel, electric motors rely on electricity, making them cleaner and often more efficient.

Electric motors come in various types, such as DC motors, AC motors, and specialized designs like stepper or brushless motors. Each serves unique purposes, but they all share core principles. Let’s explore how these motors operate, starting with the basics of their design.

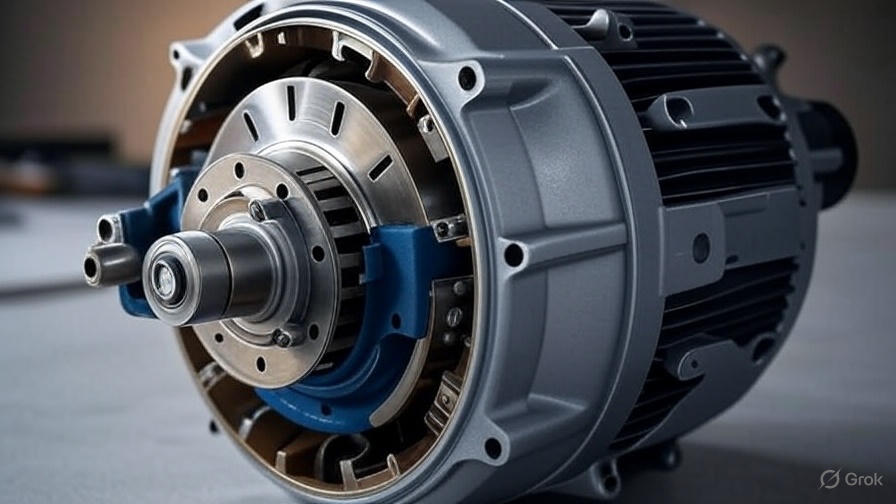

The Core Components of an Electric Motor

Every electric motor has key parts that work together to create motion. Here’s a look at the main components:

1. Rotor

The rotor is the moving part of the motor. It spins inside the motor, transferring mechanical energy to the outside world. Think of it as the heart of the motor, pumping out rotational force. Rotors are often made of conductive materials like copper or steel, designed to interact with magnetic fields.

2. Stator

The stator is the stationary part that surrounds the rotor. It generates a magnetic field, either through permanent magnets or electromagnets (coils of wire energized by electricity). This field interacts with the rotor, driving its motion.

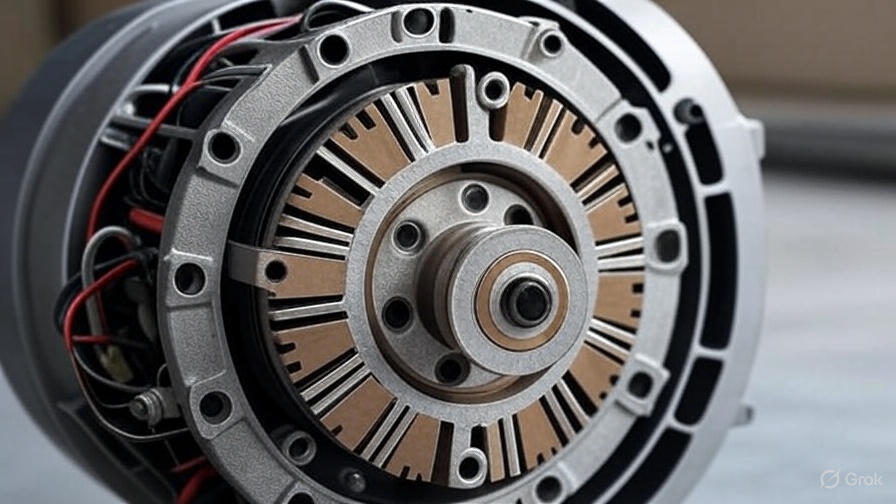

3. Armature

In some motors, the armature refers to the rotor’s conductive coils. Current flows through these coils, creating a magnetic field that interacts with the stator’s field. This interaction is what sets the rotor spinning.

4. Commutator and Brushes

In DC motors, the commutator is a segmented ring attached to the rotor. Brushes, typically made of carbon, press against the commutator to deliver electric current to the rotor’s coils. This setup ensures the rotor keeps spinning in the right direction.

5. Housing

The housing encases the motor, protecting its components and aligning them precisely. It also provides mounting points to secure the motor in place.

These parts work in harmony to produce motion. Now, let’s dive into the science that makes it all happen.

The Science Behind Electric Motors

Electric motors rely on two fundamental principles: electromagnetism and the Lorentz force. Let’s break these down in simple terms.

Electromagnetism

When electric current flows through a wire, it creates a magnetic field around it. This is electromagnetism in action. In an electric motor, coils of wire in the rotor or stator act as electromagnets. By controlling the current, the motor generates precise magnetic fields to drive motion.

Lorentz Force

The Lorentz force describes what happens when a current-carrying wire sits in a magnetic field. The wire experiences a force that pushes it perpendicular to both the current and the magnetic field. In a motor, this force acts on the rotor’s coils, causing it to spin.

Imagine a playground swing. Push it at the right moment, and it swings higher. In a motor, the magnetic fields “push” the rotor at just the right time to keep it spinning continuously. This interplay of electricity and magnetism is the secret sauce of electric motors.

How a DC Motor Works

DC motors, powered by direct current from batteries or power supplies, are common in devices like electric toys and small appliances. Here’s how they function:

- Current Flows Through the Armature: Electricity enters the rotor’s coils via the brushes and commutator. This current generates a magnetic field around the coils.

- Magnetic Fields Interact: The stator’s magnetic field (from permanent magnets or electromagnets) pushes against the rotor’s field. The Lorentz force kicks in, causing the rotor to turn.

- Commutator Switches Current: As the rotor spins, the commutator reverses the current’s direction in the coils at the right moment. This ensures the rotor keeps spinning in the same direction, as the magnetic forces align properly.

- Continuous Rotation: The cycle repeats, with the rotor spinning smoothly to produce mechanical work.

DC motors are simple and controllable, making them ideal for applications requiring precise speed adjustments, like electric vehicles or robotics.

How an AC Motor Works

AC motors run on alternating current, which constantly changes direction. You’ll find them in household appliances, HVAC systems, and industrial equipment. Their operation is slightly different:

- Stator Creates a Rotating Magnetic Field: In AC motors, the stator’s coils are energized by alternating current, producing a magnetic field that rotates around the motor. This is often achieved using multiple coils arranged in phases.

- Rotor Reacts to the Field: The rotating magnetic field induces a current in the rotor (in induction motors) or interacts with the rotor’s permanent magnets (in synchronous motors). This interaction causes the rotor to turn.

- Rotor Follows the Field: The rotor spins to “chase” the rotating magnetic field, producing continuous motion.

AC motors are robust and require less maintenance than DC motors, as they often lack brushes. They dominate in heavy-duty applications like pumps, fans, and conveyor belts.

Types of Electric Motors

Electric motors come in various flavors, each tailored to specific tasks. Here are the main types:

1. Brushed DC Motors

These use a commutator and brushes to deliver current to the rotor. They’re affordable and easy to control but require maintenance due to brush wear.

2. Brushless DC Motors

Brushless motors replace the commutator with electronic controls. They’re more efficient, durable, and common in drones, electric vehicles, and computers.

3. Induction Motors

The workhorse of AC motors, induction motors use a rotating magnetic field to induce current in the rotor. They’re reliable and widely used in industrial settings.

4. Synchronous Motors

In these AC motors, the rotor spins in sync with the stator’s magnetic field. They’re used in applications requiring precise timing, like clocks or high-speed machinery.

5. Stepper Motors

Stepper motors move in precise steps, making them perfect for robotics and 3D printers, where exact positioning is critical.

Each type has its strengths, and choosing the right one depends on the application. For example, a brushless DC motor suits a drone, while an induction motor powers a factory conveyor.

Real-World Applications of Electric Motors

Electric motors are everywhere, quietly driving modern life. Let’s explore their applications across industries:

1. Household Appliances

From washing machines to vacuum cleaners, electric motors spin drums, power fans, and drive pumps. Their compact size and efficiency make them ideal for home use.

2. Transportation

Electric vehicles rely on motors for propulsion. High-performance motors in cars like Tesla’s deliver instant torque, making them fast and efficient. Trains and trams also use powerful AC motors.

3. Industrial Machinery

Factories depend on motors to run conveyors, pumps, and robotic arms. Induction motors are especially common due to their durability and low maintenance.

4. Renewable Energy

Wind turbines use electric motors to adjust blade angles, optimizing energy capture. In some designs, motors act as generators, converting mechanical energy back into electricity.

5. Robotics and Automation

Precision motors like stepper and brushless DC motors power robotic arms and automated systems, enabling tasks from assembly lines to surgical robots.

These applications show the versatility of electric motors. Their ability to scale from tiny devices to massive industrial systems makes them indispensable.

Advantages of Electric Motors

Why are electric motors so popular? Here are some key benefits:

- Efficiency: Electric motors convert a high percentage of electrical energy into mechanical work, often exceeding 90% efficiency.

- Eco-Friendly: They produce no emissions, making them a green alternative to combustion engines.

- Low Maintenance: Especially in brushless and induction motors, fewer moving parts mean less wear and tear.

- Versatility: Motors come in various sizes and types, fitting countless applications.

- Control: Advanced electronics allow precise control over speed and torque, especially in DC motors.

These advantages explain why electric motors are a cornerstone of modern technology.

Challenges and Limitations

No technology is perfect. Electric motors face a few challenges:

- Power Supply Dependence: Motors need a reliable electricity source, limiting their use in remote areas.

- Heat Generation: High-performance motors can overheat, requiring cooling systems.

- Cost: Advanced motors, like brushless DC or high-efficiency models, can be expensive.

- Size Constraints: Large motors for heavy-duty applications can be bulky, posing design challenges.

Despite these hurdles, ongoing advancements in materials and electronics continue to improve motor performance.

Innovations in Electric Motor Technology

The world of electric motors is evolving. Engineers are pushing boundaries to make motors smaller, more efficient, and more powerful. Here are some exciting trends:

1. High-Efficiency Materials

New magnetic materials, like rare-earth magnets, boost motor performance. These materials create stronger magnetic fields, improving torque and efficiency.

2. Smart Motors

Integrating sensors and IoT technology allows motors to monitor their own performance. Smart motors can adjust speed, detect faults, and optimize energy use in real time.

3. Compact Designs

Advances in materials and manufacturing enable smaller, lighter motors without sacrificing power. This is critical for electric vehicles and portable devices.

4. Regenerative Braking

In electric vehicles, motors can act as generators during braking, converting kinetic energy back into electricity to recharge batteries.

These innovations ensure electric motors remain at the forefront of technology, driving progress in countless fields.

How to Choose the Right Electric Motor

Selecting an electric motor depends on your needs. Here are some factors to consider:

- Power Requirements: Calculate the torque and speed needed for your application.

- Power Source: Decide between AC or DC based on your available electricity.

- Environment: Consider factors like temperature, dust, or moisture, which affect motor durability.

- Budget: Balance upfront costs with long-term efficiency and maintenance savings.

- Control Needs: If precision is key, opt for stepper or brushless DC motors with advanced controls.

Consulting with a motor specialist can help you pick the perfect model for your project.

Maintaining Electric Motors

Proper maintenance extends a motor’s lifespan. Here are some tips:

- Regular Inspections: Check for wear, especially on brushes in DC motors.

- Lubrication: Keep bearings lubricated to reduce friction.

- Cleanliness: Remove dust and debris to prevent overheating.

- Cooling: Ensure adequate ventilation to manage heat buildup.

- Electrical Checks: Monitor voltage and current to avoid overloading.

Routine care keeps motors running smoothly and prevents costly downtime.

The Future of Electric Motors

Electric motors are poised for a bright future. As the world shifts toward sustainability, their role in electric vehicles, renewable energy, and automation will grow. Governments and industries are investing heavily in electrification, driving demand for efficient, powerful motors.

Emerging technologies, like artificial intelligence and advanced materials, will further enhance motor performance. For example, AI can optimize motor control for maximum efficiency, while new alloys reduce weight and cost. The push for greener energy also means motors will play a bigger role in wind, solar, and hydrogen systems.

Conclusion

Electric motors are marvels of engineering, turning electricity into motion with elegance and efficiency. From their core components to the principles of electromagnetism, they embody the beauty of physics in action. Whether spinning the wheels of an electric car or powering a factory, these devices shape our world.

By grasping how electric motors work, you gain insight into a technology that’s everywhere yet often overlooked. As innovations continue, their impact will only grow, making them a key player in a sustainable, electrified future.