Two-stroke engines power millions of devices around the world, from chainsaws and leaf blowers to motorcycles and marine outboards. These compact powerhouses deliver impressive performance despite their simple design. This comprehensive guide explores the inner workings of two-stroke motors, their advantages, disadvantages, and real-world applications.

What Makes a Two-Stroke Engine Different?

A two-stroke engine completes its power cycle in just two piston movements – one upward stroke and one downward stroke. This differs significantly from four-stroke engines, which require four piston movements to complete the same cycle. The fundamental difference lies in how these engines handle the intake, compression, combustion, and exhaust processes.

In a four-stroke engine, each process occurs during a separate stroke. However, two-stroke engines compress multiple processes into each stroke, creating a more efficient power delivery system. This compression of processes results in a power stroke with every revolution of the crankshaft, compared to every other revolution in four-stroke engines.

The Basic Components of a Two-Stroke Engine

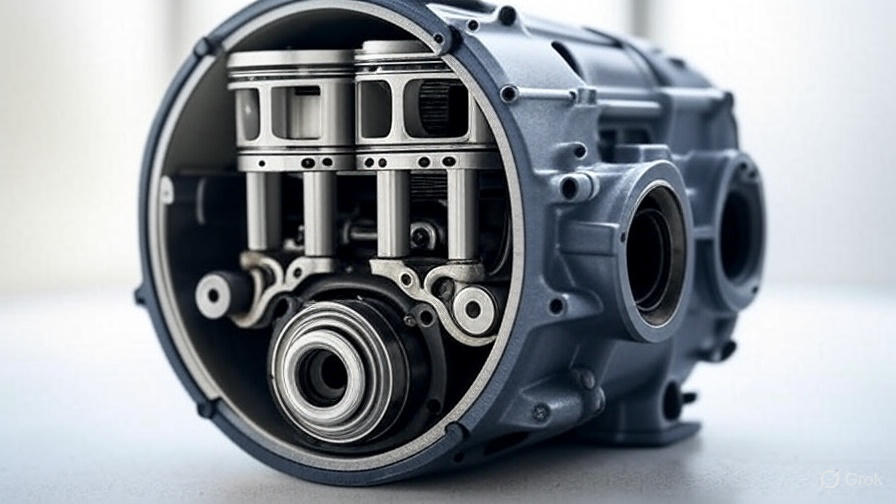

Every two-stroke engine contains several essential components that work together to create power. The cylinder houses the piston, which moves up and down to create compression and power. The crankshaft converts the linear motion of the piston into rotational motion that drives the output shaft.

The combustion chamber sits at the top of the cylinder, where the fuel-air mixture ignites. Ports in the cylinder walls serve as pathways for air, fuel, and exhaust gases. These ports replace the complex valve systems found in four-stroke engines.

The crankcase plays a crucial role in two-stroke operation, serving as both a support structure and part of the engine’s breathing system. Unlike four-stroke engines, the crankcase in two-stroke motors actively participates in the intake process.

The Two-Stroke Cycle Explained

First Stroke: Compression and Intake

The first stroke begins with the piston moving upward from bottom dead center (BDC) to top dead center (TDC). As the piston rises, it compresses the fuel-air mixture that entered the cylinder during the previous cycle. This compression heats the mixture and prepares it for efficient combustion.

Simultaneously, the upward movement of the piston creates a vacuum in the crankcase below. This vacuum draws fresh fuel-air mixture through the intake port into the crankcase. The crankcase acts as a temporary storage chamber for the incoming charge.

During this stroke, the piston crown blocks the exhaust port, preventing compressed gases from escaping. The intake port remains open to the crankcase, allowing the fresh mixture to enter the lower chamber.

Second Stroke: Power and Exhaust

The second stroke begins when the spark plug ignites the compressed fuel-air mixture at TDC. The explosion forces the piston downward with tremendous force, creating the power stroke that drives the crankshaft.

As the piston descends, it compresses the fresh fuel-air mixture stored in the crankcase. Near the bottom of the power stroke, the piston uncovers the exhaust port, allowing burned gases to escape from the cylinder.

Continued downward movement of the piston opens the intake port, releasing the compressed fresh mixture from the crankcase into the cylinder. This fresh mixture helps push out remaining exhaust gases through the exhaust port, a process called scavenging.

Port Timing and Scavenging

Port timing determines when intake, exhaust, and transfer events occur during the engine cycle. The size, shape, and position of ports significantly affect engine performance, power delivery, and fuel efficiency.

Scavenging describes how fresh fuel-air mixture displaces burned exhaust gases from the cylinder. Effective scavenging ensures complete removal of exhaust gases while minimizing the loss of fresh mixture through the exhaust port.

Three main scavenging methods exist in two-stroke engines: cross-flow, loop, and uniflow scavenging. Cross-flow scavenging uses ports positioned on opposite sides of the cylinder. Loop scavenging employs multiple ports that create a circular flow pattern. Uniflow scavenging uses intake ports at the bottom and exhaust valves at the top.

Fuel Delivery Systems

Two-stroke engines use various fuel delivery methods, each with distinct characteristics and applications. Carburetor systems mix fuel and air before entering the engine, providing simple and reliable operation for many applications.

Traditional carburetors use venturi principles to create the proper fuel-air mixture. The operator controls engine speed by adjusting the throttle, which regulates airflow through the carburetor. This system works well for applications with varying load conditions.

Direct injection systems inject fuel directly into the combustion chamber, offering precise fuel control and improved efficiency. These systems use electronic controls to optimize fuel delivery based on engine conditions, resulting in better performance and lower emissions.

Lubrication in Two-Stroke Engines

Two-stroke engines require different lubrication methods compared to four-stroke engines. Since the crankcase participates in the intake process, it cannot hold a reservoir of lubricating oil like four-stroke engines.

Pre-mix lubrication involves mixing oil directly with the fuel before entering the engine. The oil burns along with the fuel, providing lubrication to engine components during operation. This method requires careful attention to oil-to-fuel ratios to ensure adequate lubrication without excessive smoke or carbon buildup.

Auto-lube systems automatically inject oil into the fuel stream or directly onto critical components. These systems use pumps and metering devices to deliver precise amounts of oil based on engine speed and load conditions. Auto-lube systems provide consistent lubrication while eliminating the need for manual fuel mixing.

Advantages of Two-Stroke Engines

Two-stroke engines offer several compelling advantages that make them ideal for specific applications. Their simple design contains fewer moving parts than four-stroke engines, reducing manufacturing costs and maintenance requirements.

The power-to-weight ratio of two-stroke engines exceeds that of comparable four-stroke engines. This advantage makes them perfect for handheld tools, motorcycles, and marine applications where weight matters.

Two-stroke engines produce power with every crankshaft revolution, providing smooth power delivery and high power output relative to engine size. This characteristic makes them excellent for applications requiring compact, powerful motors.

The absence of valve mechanisms simplifies engine design and reduces potential failure points. Two-stroke engines can operate in any orientation, making them suitable for chainsaws, trimmers, and other handheld equipment.

Disadvantages and Limitations

Despite their advantages, two-stroke engines have notable limitations that affect their suitability for certain applications. Fuel consumption tends to be higher than four-stroke engines because some fresh fuel-air mixture escapes through the exhaust port during scavenging.

Emissions from two-stroke engines typically exceed those from four-stroke engines. The scavenging process allows unburned fuel to escape, contributing to hydrocarbon emissions. Oil burning in pre-mix lubrication systems adds to particulate emissions.

Two-stroke engines generally produce more noise than four-stroke engines due to their rapid firing rate and exhaust characteristics. This noise can be problematic in residential areas or noise-sensitive applications.

The power delivery characteristics of two-stroke engines can be abrupt, making them less suitable for applications requiring smooth, controllable power output. This trait affects their use in vehicles requiring precise throttle control.

Common Applications

Two-stroke engines excel in applications where their unique characteristics provide clear advantages. Handheld power tools like chainsaws, string trimmers, and leaf blowers benefit from the lightweight, high-power output of two-stroke motors.

Marine outboard motors frequently use two-stroke engines because they provide excellent power-to-weight ratios and can operate reliably in marine environments. The ability to operate in any orientation makes them suitable for tilting and steering applications.

Motorcycles and scooters, particularly in developing countries, often use two-stroke engines for their simplicity and low cost. Racing motorcycles sometimes employ two-stroke engines for their high power output and lightweight design.

Small aircraft and ultralight planes sometimes use two-stroke engines because weight savings are critical for flight performance. The high power-to-weight ratio makes them attractive for aviation applications despite their higher fuel consumption.

Maintenance and Troubleshooting

Proper maintenance ensures reliable operation and extends the life of two-stroke engines. Regular inspection of the spark plug reveals engine operating conditions and can identify potential problems before they become serious.

Air filter maintenance is crucial because two-stroke engines are sensitive to airflow restrictions. Dirty air filters reduce performance and can cause rich fuel mixtures that lead to carbon buildup and poor combustion.

Fuel system maintenance includes using fresh fuel, proper oil mixing ratios, and clean fuel filters. Old or contaminated fuel can cause starting problems and poor performance. Incorrect oil ratios can lead to engine damage or excessive smoke.

Exhaust system maintenance involves checking for blockages that can restrict exhaust flow and reduce performance. Carbon buildup in the exhaust port or muffler can significantly impact engine operation.

Performance Modifications

Enthusiasts often modify two-stroke engines to increase power output or improve performance characteristics. Port modifications can alter timing and flow characteristics to optimize power delivery for specific applications.

Carburetor modifications or replacements can improve fuel delivery and throttle response. Larger carburetors can support higher power outputs, while different needle and jet combinations fine-tune fuel delivery across the rpm range.

Exhaust system modifications significantly impact two-stroke performance. Expansion chambers use pressure waves to improve scavenging and increase power output. The design of these chambers must match engine characteristics for optimal results.

Ignition system upgrades can provide more precise timing control and stronger spark energy. Electronic ignition systems offer consistent timing and eliminate the need for points and condenser maintenance.

Environmental Considerations

Environmental concerns have led to stricter regulations governing two-stroke engine emissions. Many regions have implemented standards that limit hydrocarbon, carbon monoxide, and particulate emissions from small engines.

Modern two-stroke engines incorporate various technologies to reduce emissions while maintaining performance. Stratified charging systems separate oil and fuel layers to reduce oil consumption and emissions. Catalytic converters in exhaust systems help reduce harmful emissions.

Direct injection technology represents a significant advancement in two-stroke engine design. These systems inject fuel directly into the combustion chamber after the exhaust port closes, preventing fuel loss and reducing emissions.

The Future of Two-Stroke Technology

Research and development continue to improve two-stroke engine technology. Electronic fuel injection systems provide precise fuel control and enable compliance with strict emission standards while maintaining the performance advantages of two-stroke design.

Hybrid systems combining two-stroke engines with electric motors offer potential solutions for applications requiring both high power output and environmental compliance. These systems can optimize operation for specific conditions while reducing overall emissions.

Alternative fuels and lubricants designed specifically for two-stroke engines may help address environmental concerns while maintaining performance benefits. Biodegradable oils and cleaner-burning fuels could extend the viable applications for two-stroke technology.

Conclusion

Two-stroke engines continue to serve important roles in modern society despite environmental challenges. Their unique combination of simplicity, light weight, and high power output makes them irreplaceable in many applications. As technology advances, two-stroke engines are adapting to meet stricter environmental standards while maintaining their fundamental advantages.

The future of two-stroke technology lies in balancing performance requirements with environmental responsibility. Through continued innovation in fuel delivery, lubrication, and emission control systems, two-stroke engines will likely remain viable for specific applications where their unique characteristics provide clear advantages over four-stroke alternatives.

For anyone working with two-stroke engines, understanding their operation principles, maintenance requirements, and limitations is essential for safe and effective use. Whether powering a chainsaw, outboard motor, or motorcycle, these remarkable engines continue to demonstrate the elegance of simple, effective engineering solutions.