A carburetor is the heart of many internal combustion engines, blending air and fuel to power everything from classic cars to lawnmowers. Though modern vehicles often rely on fuel injection systems, carburetors remain a fascinating piece of engineering, especially for enthusiasts of vintage motorcycles, small engines, or classic automobiles. This blog post dives deep into the mechanics of how a carburetor works, breaking down its components, functions, and processes in a way that’s easy to grasp. By the end, you’ll have a solid grip on this critical engine component and why it matters. Let’s get started!

What Is a Carburetor?

A carburetor is a mechanical device that mixes air with a fine spray of liquid fuel, creating a combustible mixture for an internal combustion engine. Think of it as a chef carefully blending ingredients to create the perfect dish. The carburetor ensures the engine gets the right balance of air and fuel to run smoothly, whether idling at a stoplight or roaring down the highway.

Carburetors were standard in vehicles before electronic fuel injection systems took over in the late 20th century. Today, they’re still common in smaller engines, like those in chainsaws, motorcycles, and boats. Their simplicity, reliability, and ease of repair make them a favorite among DIY mechanics and hobbyists.

Why Does a Carburetor Matter?

Engines need a precise air-fuel mixture to operate efficiently. Too much fuel (a “rich” mixture) wastes gas and creates excess emissions. Too little fuel (a “lean” mixture) causes the engine to sputter or stall. The carburetor’s job is to deliver the perfect ratio—typically around 14.7 parts air to 1 part fuel, known as the stoichiometric ratio—for optimal combustion. This balance maximizes power, fuel efficiency, and engine longevity.

Now, let’s explore the key components of a carburetor and how they work together to keep an engine humming.

Key Components of a Carburetor

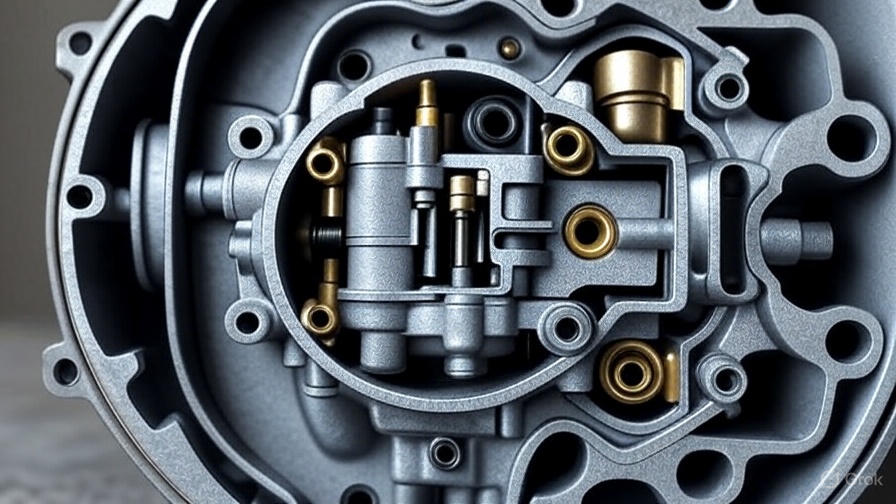

A carburetor is a complex assembly of parts, each playing a specific role. Here’s a breakdown of the main components:

1. Venturi

The venturi is a narrow section of the carburetor’s air passage that speeds up airflow. As air rushes through this bottleneck, it creates a low-pressure zone, drawing fuel into the airstream. This principle, called the Venturi effect, is the backbone of how carburetors mix air and fuel.

2. Float Chamber

The float chamber, or float bowl, holds a small reservoir of fuel. A float, similar to the one in a toilet tank, regulates the fuel level. When the fuel level drops, the float lowers, opening a valve to let more fuel in from the gas tank. This ensures a steady supply of fuel for the carburetor to work with.

3. Jets

Jets are tiny, precisely calibrated openings that control the flow of fuel into the airstream. The main jet handles fuel delivery during high-speed operation, while the idle jet takes over when the engine is running at low speeds. Some carburetors also have a pilot jet for fine-tuning the mixture.

4. Throttle Valve

The throttle valve, often a flat disc called a butterfly valve, regulates the amount of air entering the carburetor. When you press the gas pedal or twist the throttle on a motorcycle, the valve opens, allowing more air and fuel to enter the engine, increasing power output.

5. Choke

The choke restricts airflow to enrich the fuel mixture, making it easier to start a cold engine. By reducing air intake, the choke increases the proportion of fuel in the mixture, which helps the engine fire up when it’s not yet warmed up.

6. Air and Fuel Passages

These are the pathways where air and fuel travel within the carburetor. Air enters through an intake, passes through the venturi, and mixes with fuel from the jets before heading to the engine’s cylinders.

Each of these components works in harmony to ensure the engine gets the right air-fuel mixture at the right time. Next, let’s dive into the step-by-step process of how a carburetor operates.

How a Carburetor Works: Step-by-Step

The carburetor’s operation is a beautifully orchestrated process. Here’s how it all comes together:

Step 1: Air Enters the Carburetor

When the engine runs, it creates a vacuum that pulls air through the carburetor’s air intake. The throttle valve controls how much air enters. At idle, the valve is nearly closed, allowing just a trickle of air. When you accelerate, the valve opens wide, letting in a rush of air.

Step 2: The Venturi Effect Kicks In

As air flows through the venturi, the narrow passage speeds up the airflow, reducing pressure. This low-pressure zone acts like a vacuum, sucking fuel from the float chamber through the jets. The faster the air moves (like when you rev the engine), the more fuel gets pulled into the mix.

Step 3: Fuel and Air Mix

The fuel, now a fine mist, blends with the incoming air in the venturi. This creates the combustible air-fuel mixture that the engine needs. The jets ensure the right amount of fuel is added, maintaining the ideal air-fuel ratio for combustion.

Step 4: Mixture Enters the Engine

The air-fuel mixture travels through the carburetor’s passages and into the engine’s cylinders. Here, a spark from the spark plug ignites the mixture, driving the pistons and powering the engine. The throttle valve’s position determines how much mixture reaches the cylinders, controlling the engine’s speed and power.

Step 5: Adjustments for Different Conditions

The carburetor adapts to different operating conditions. For example:

- Cold starts: The choke restricts airflow, creating a richer mixture to help the engine start.

- Idle: The idle jet provides a small amount of fuel for low-speed operation.

- High speeds: The main jet takes over, delivering more fuel to match the increased airflow.

This dynamic process happens continuously as you drive, ensuring the engine runs smoothly under varying conditions.

Types of Carburetors

Not all carburetors are the same. Different designs suit different engines and applications. Here are the main types:

1. Updraft Carburetor

In an updraft carburetor, air enters from below and flows upward through the carburetor. These were common in early vehicles but are less efficient due to gravity’s effect on fuel flow.

2. Downdraft Carburetor

Downdraft carburetors have air flowing downward, which is more efficient because gravity helps pull the fuel into the airstream. Most modern carburetors use this design.

3. Sidedraft Carburetor

Sidedraft carburetors have air entering horizontally, often used in high-performance engines like those in motorcycles or racing cars. They provide excellent airflow for maximum power.

4. Multi-Barrel Carburetor

Multi-barrel carburetors, like two-barrel or four-barrel models, have multiple venturis and throttle valves. These deliver more air and fuel for larger, high-performance engines, such as those in muscle cars.

Each type has its strengths, but they all rely on the same basic principles of air and fuel mixing.

Common Carburetor Problems and Solutions

Like any mechanical device, carburetors can develop issues. Here are some common problems and how to fix them:

1. Clogged Jets

Dirt or debris can block the jets, disrupting the fuel flow. This leads to a lean mixture, causing the engine to misfire or stall.

- Solution: Clean the jets with carburetor cleaner and compressed air. Disassemble the carburetor carefully and inspect all passages.

2. Stuck Float

A stuck float can cause the float chamber to overfill or run dry, leading to flooding or fuel starvation.

- Solution: Remove the float bowl and check the float for free movement. Replace any damaged components.

3. Worn Needle Valve

The needle valve, which works with the float, can wear out, causing improper fuel levels.

- Solution: Replace the needle valve and ensure the float is properly adjusted.

4. Dirty Air Filter

A clogged air filter restricts airflow, creating a rich mixture that reduces efficiency and power.

- Solution: Replace or clean the air filter regularly to maintain proper airflow.

Regular maintenance, like cleaning and tuning, keeps a carburetor in top shape. Many enthusiasts enjoy the hands-on process of rebuilding a carburetor, as it’s relatively straightforward with the right tools.

Carburetor vs. Fuel Injection: What’s the Difference?

Carburetors and fuel injection systems both deliver air and fuel to the engine, but they differ in design and operation. Fuel injection uses electronic sensors and injectors to precisely control the air-fuel mixture, offering better efficiency and emissions control. Carburetors, by contrast, rely on mechanical processes, making them simpler but less precise.

Why do some prefer carburetors? They’re easier to repair, more affordable, and give a hands-on feel that enthusiasts love. Fuel injection systems, while efficient, require specialized tools and knowledge for maintenance.

Tuning a Carburetor for Performance

Tuning a carburetor optimizes the air-fuel mixture for specific conditions, like high-altitude driving or racing. Here’s a basic guide:

- Adjust the Idle Speed: Use the idle screw to set the engine’s idle speed to the manufacturer’s specifications.

- Set the Air-Fuel Mixture: Turn the mixture screw to find the sweet spot where the engine runs smoothly without bogging down.

- Check the Float Level: Ensure the float is set to the correct height to maintain proper fuel levels.

- Test and Fine-Tune: Take the vehicle for a test drive and make small adjustments to achieve peak performance.

Proper tuning requires patience and a good ear for how the engine sounds. Many mechanics use a tachometer to monitor engine RPM during adjustments.

The Role of Carburetors in Modern Engines

While fuel injection dominates modern vehicles, carburetors still have a place in small engines and specialty applications. Chainsaws, leaf blowers, and classic motorcycles often use carburetors due to their simplicity and cost-effectiveness. Enthusiasts also keep carburetors alive in restored vintage cars, valuing their nostalgic charm and mechanical purity.

Environmental Impact of Carburetors

Carburetors are less efficient than fuel injection systems, leading to higher emissions. This is one reason why automakers switched to fuel injection in the 1980s and 1990s, as stricter emissions regulations took hold. However, modern carburetors in small engines are designed to meet environmental standards, with features like catalytic converters to reduce emissions.

Fun Facts About Carburetors

- The first carburetor was invented in 1888 by Karl Benz, the founder of Mercedes-Benz.

- Carburetors were used in aircraft engines during World War II, requiring special designs to handle extreme conditions.

- The term “carburetor” comes from the French word “carbure,” meaning “carbide,” referring to the chemical process of mixing fuel.

Conclusion

A carburetor is a marvel of mechanical engineering, transforming air and fuel into the power that drives engines. By blending the Venturi effect, precise fuel delivery, and clever components like the float and jets, carburetors keep engines running smoothly across a range of conditions. Whether you’re a gearhead restoring a classic car or a curious beginner learning about engines, understanding how a carburetor works opens a window into the world of internal combustion.

From its role in vintage vehicles to its continued use in small engines, the carburetor remains a testament to simple, effective design. With proper maintenance and tuning, it can deliver reliable performance for years. So, the next time you fire up a carbureted engine, take a moment to appreciate the intricate dance of air and fuel happening inside that small but mighty device.